How Mattress Packaging Machine Boosts Packaging Speed ?

- By:Zhonglian

- 2023-01-06

- 156

Mattress packaging machines compress and seal mattresses into sheets for roll packaging. This approach reduces shipping costs and storage space. It can also be customized to meet customer’s requirements. The machine is available in a variety of designs to suit the needs of mattress manufacturers. Below are some of the features of this machine. These machines are great for making mattresses. They are widely used and can be found in today market and factories, If you have any questions or would like more information, please contact us today!

Why Use A Mattress Packaging Machine ?

Mattress packing machine is a compact machine for compressing and rolling mattresses. It’s not an automatic bagger, but it offers high efficiency and is highly compatible with other types of compression mattresses. Its automation features make the packaging process simple and convenient. All necessary steps are performed by a single worker, making it ideal for direct-to-consumer and retail markets. It is an essential part of any mattress factory and should be used by all manufacturers. It uses a syringe to provide continuous high pressure to the product while sealing the vacuum bag. The process minimizes the volume of the product, even for large products, by up to 50%. The machine has a microcontroller that helps to change settings without rebooting the machine. It’s fully automatic, making it easy to adjust settings, make changes, or even replace cylinders.

Benefits of Mattress Packaging Machine

The most important benefit of a mattress packaging machine is its ease of use. It comes with an easy-to-read digital screen that provides information on the status of the product. The touch screen display makes it easy to see if the machine is functioning properly. Operators can easily check the condition of the product. If it works fine, it’s not too hard to wrap. If not, users can simply adjust the settings to make the process easier The automatic mattress packaging machine can save manpower and improve efficiency. These machines can be integrated with other machines in the production line to make packaging easier and more efficient. They are ideal for making mattresses, sponges and other products. In addition to being easier to transport, packaged mattresses are also safer. You don’t need to worry about shipping your product as your packaging will do it for you. It is easy to clean, maintain and carry.

Purchasing a mattress packaging machine can be a great investment for your business. Not only can it save you money on transportation costs, it can also increase your efficiency, and save you storage space. Our new mattress packaging machines to help reduce transportation costs. These machines are easy to use, convenient to operate, and have a modular design. This means they can be incorporated with other machines for increased productivity. Besides, Using the mattress packaging machine is a cost-effective way to protect your mattress during transportation and warehousing. Using a mattress packaging machine is also an excellent way to save storage space. The size of the box is reduced allowing for more efficient logistics. Besides, using a mattress packaging machine is easy to maintain. This means that you don’t have to worry about tools getting lost in the shuffle. A mattress packaging machine may be used for various types of mattresses including memory foam, latex, and pocket coil spring. This machine is able to compress and roll these types of mattresses. It can also be used to fold the mattress in thirds.

Several manufacturers of mattress packaging machines are seeking ways to improve their equipment’s performance and efficiency. Some are making machines that roll mattresses two times, which allows them to be inserted into smaller boxes and minimizes shipping costs. It can be bought at a low price in China. Compared with similar machines, it provides better quality and efficiency. Also, it doesn’t require compression. The final product can be shipped directly to the customer. With this, it is very cost-effective for manufacturers. Its modular design makes it easy to install and maintain. The machine will reduce shipping and storage costs. In addition, the machine is easy to install and maintain.

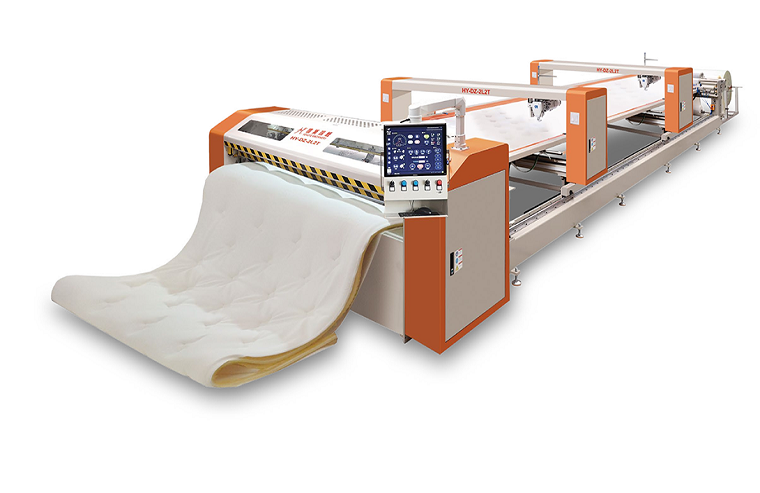

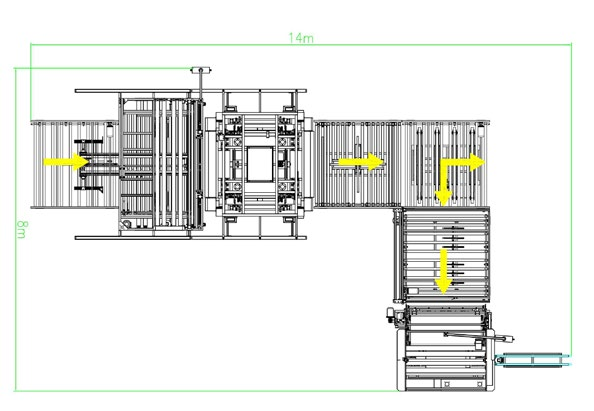

Full Automatic Mattress Packaging Line YK-FCR

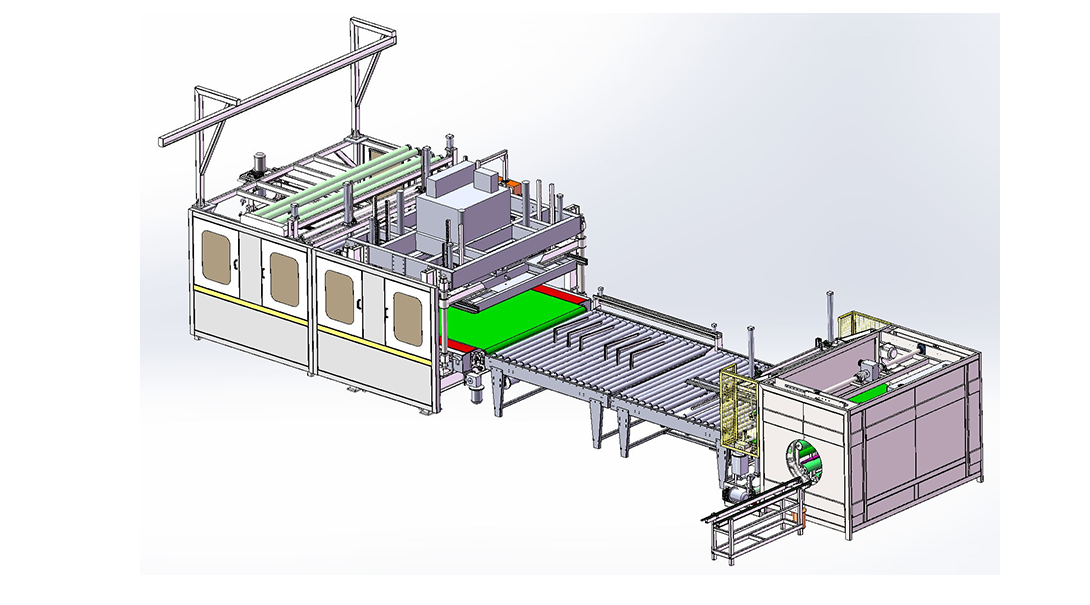

The mattress vacuum packing machine is mainly used for the compression of sponge mattresses and spring mattresses. The mattress vacuum packing machine has a professional electronic control system, which can ensure that mattresses of different models and thicknesses can be quickly compressed without damaging the mattress. Whether you’re looking for a machine to compress your mattress, bolsters, pillows, Zhonglian has your back. Among its products, the Vacuum Compressing Packaging Machine YK-MCP is the go-to machine for high volume mattress and cushion manufacturers. The machine comes equipped with many features to improve production output and reduce operational costs.

It’s also one of the best choices for mattress manufacturers looking to improve profit margins while maintaining a high level of customer satisfaction. The compression of the mattress is automatically completed by the conveyor belt from the inlet to the outlet, with functions such as automatic vacuuming and automatic heat sealing. Using the mattress vacuum packing machine saves time and effort, reduces labor intensity, improves processing efficiency, and greatly saves storage and transportation space and costs.

What Should Consider When Buying a Mattress Packing Machine

For anyone who is planning to buy a mattress packing machine, it is important to do some research so that you can make the right choice. This article will cover a few different factors to consider. is a new mattress packing machine that allows mattresses to be rolled twice before being packed into a smaller box.

The mattress compression machine is used to compress spring mattresses and foam mattresses. It saves storage space and freight cost as it compresses them into thin sheets. In addition, it has the functions of heat sealing and vacuum pumping. By using this machine, you can easily compete in the retail marketplace. Vacuum compression packaging is a great way to compress various mattress models and thicknesses. This machine is designed with a professional electronic control system. This system can rapidly compress the matress. It can be equipped with a PLC-based control system to ensure the operation of the machine. And it is very simple to operate. Once the worker puts the mattress into the plastic bag, he or she can simply put it into the machine. The machine will automatically finish the process of compression.

A mattress that is rolled once can fit into a box measuring only 0.16 cubic meters while a double rolled version can fill a box that is only 1.20 cubic meters. It is an effective way of minimizing the number of shipping pallets required. The other main feature of this type of machine is that it can be customized to meet the manufacturer’s specific needs. This type of machine has the capabilities of compressing, wrapping, folding, and assembling mattresses. These functions can handle a wide range of mattress sizes, including those as small as 10 inches in diameter. When a mattress arrives, the system automatically selects the optimal packaging film size for that specific product. Moreover, the system is able to handle the three major types of mattresses: foam, latex, and pocket springs. With this, manufacturers can produce the best mattresses with minimum operator intervention.

-

Automatic Tape Edge Machine VS Semi-Auto Tape Edge Machine

2024/06/27 -

Revolution of Computerized Multi-Needle Quilting Machine

2024/05/23 -

Is Lubrication Necessary for Mattress Sewing Machines?

2024/05/15 -

How Mattress Packaging Machine Boosts Packaging Speed ?

2023/01/06 -

Mattress Automation with Tape Edge Machine

2022/04/20 -

How to Choose Mattress Sewing Machine

2022/04/20